Cable & Tube

Wall Thickness Measurement

Increase Production Efficiencies, Reduce Material Costs

Most tube extrusion operators run the line at sizes that are well above the minimum specifications in order to ensure that they do not create scrap product. This ensures that the extrusion line is at a maximum of up-time, but also creates a scenario where all finished product includes a high amount of material give away.

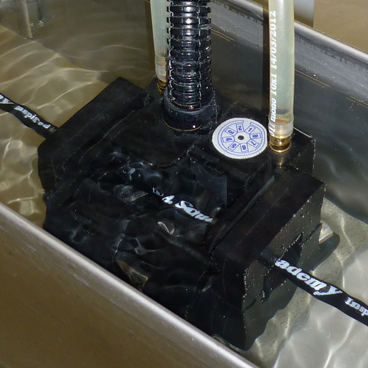

The BETA LaserMike UltraScan Pro gauge continuously monitors product dimensions by using multiple transducers to provide full measurement coverage. This allows for the calculation of concentricity and the determination of the minimum and maximum wall thickness. This concentricity improvement of the product allows the average wall to run closer to the minimum specification without one side of the wall going below specification.

Learn more about the UltraScan Pro gauge below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP