Cable & Tube

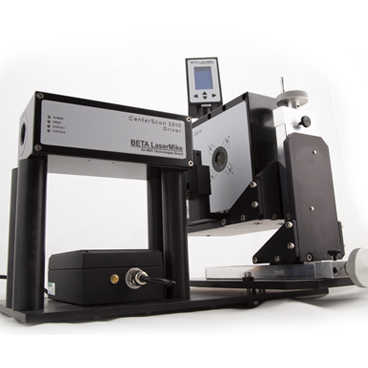

CapScan

Drift-Free, In-Process Capacitance Measurement System

Realize greater accuracy and consistency between in-process and post-process capacitance measurements to increase quality yields and product output.

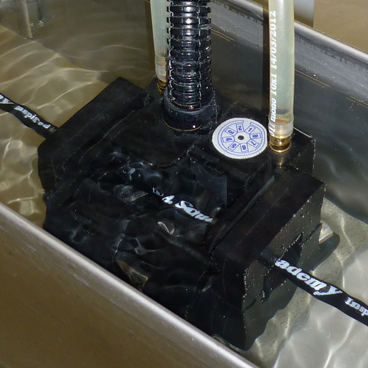

- High-Accuracy Gauging – obtain accurate readings on wet or dry trough installations at line speeds up to 3,000 m/min

- Worry-Free Operation – benefit from enhanced accuracy via unique self-balancing bridge, auto gain and auto self-calibration

- Real-Time Analysis – use fast analog output for FFT/SRL analysis to eliminate costly SRL failures with DataCom, Coaxial and any high-frequency cables

- Flexible Connectivity – supports Profibus, DeviceNet, RS-232 and Analog for easy connection to PLCs, PCs or a BETA LaserMike controller

- Lowest TCO – rugged, high-performance design minimizes maintenance and provides long, reliable service life

- Preeminent Support – all systems are backed by NDC's dedicated worldwide customer service organization available 24-7 via myNDC cloud service

Contact us today to learn how our CapScan gauges can give you the competitive advantage.

A Range of Capacitance Measurement Options to Meet Your Application Needs

CapScan offers various gauge heads for measuring cables up to 25 mm with bandwidths up to 10 GHz. Gauges can be mounted in-trough and used for a broad scope of communication cable applications.

CapScan can be easily connected to the Beta LaserMike KI1000 Indicator for simple, reliable data indication. The KI1000 connects to the CapScan gauge via CANBUS and provides quick response so you can easily monitor product changes in real time.

Contact us today to learn more on how CapScan can give you the product quality advantage through accurate, consistent cable capacitance measurements.