Metals Processing

Strip Processing Line

Ensure High-Cost Efficiency from High-Accuracy Length and Speed Measurements

As an aluminum manufacturer, you want to make sure that your operation cost-effectively converts the flat coiled strip into the quality products specified by your customers. The equipment you employ in your process represents significant capital to produce these high-value products. Because of these factors, many companies place a great deal of emphasis on employing the most effective and reliable measurement system to control the speed of the strip processing line and ultimate length dimensions of the final product.

Non-Contact Laser Gauging Provides Optimum Process Control

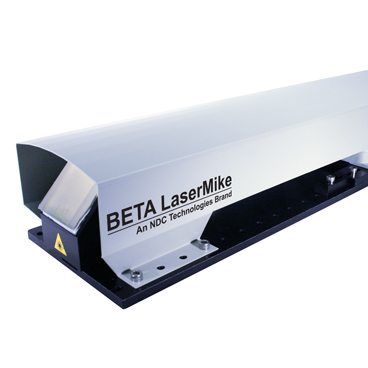

NDC offers the LaserSpeed® Pro non-contact gauge to directly measure the length and speed of moving product at the strip processing line. This gauge is a proven alternative to using error-prone mechanical contact encoders. The LaserSpeed Pro gauge uses a unique, laser-based technique to precisely measure the speed of the strip and then converts this data into pulses per unit length which is then used to accurately determine product length. Velocity measurements are used to control the speed of the strip processing line, and integrated over time to calculate the coil length. Pulses, or a data stream containing velocity and length, can also be sent to a PLC system to control cut-to-length or slitting operations to produce product to the exact length dimensions. Length and speed measurements are made with better than +/-0.03% accuracy, +/-0.02% repeatability.

Manufacturers are realizing real productivity gains with this technology by significantly reducing process speed and length measurement errors and improving process control.

Check out our gauging solutions below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP