Copper, Brass and Other Metals

Implementing Accurate, Non-Contact Length and Speed Measurements

Accurate length and speed measurements on products in copper, bronze and other metals manufacturing processes have been very difficult due to a number of mechanical system challenges, such as heat, debris build-up and the deterioration of mechanical parts. Yet, many metals producers still use mechanical contact encoders, such as wheel tachometers, to perform these product measurements.

Contact-type measurement systems by design do not directly measure the product and do a poor job of capturing the actual length and speed with any degree of accuracy. These mechanical systems are subject to slippage and calibration changes caused by variations in the diameter of the measurement wheel due to dirt build-up or wear. In addition, it is extremely difficult to obtain accurate measurements in harsh manufacturing environments.

LaserSpeed Pro is Proven on All Types of Applications

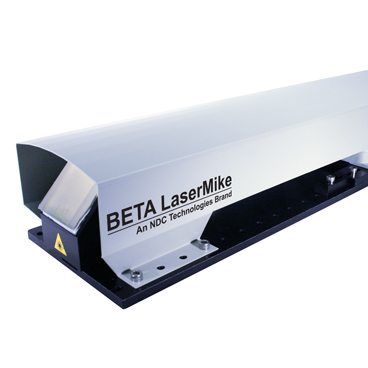

Manufacturers across a wide range of metals manufacturing processes are using the LaserSpeed® Pro non-contact gauge because it eliminates the measurement errors associated with contact measurement techniques. This laser-based, higher precision gauge is cost effective and used in many hot and cold metals applications today. Examples include measuring continuous product length, cut control, elongation control and gauge control in plate mills, temper mills, foil lines, bar/rod mills, rod drawing lines, pipe and tube mills, extrusion lines, and wire and cable drawing lines, to name few.

The LaserSpeed Pro gauge can measure product length and speed with better than +/-0.03% accuracy and without contacting the product. It can also detect forward or reverse product direction and down to true zero speed (when the line is at a complete standstill). It is a direct replacement for error-prone contact encoders.

Check out our gauging solution below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP