Metals Processing

Cold Rolling Mill

Ensure High Accuracy and Yields in Your Cold Mill

Accurate length and speed measurements for the cold rolling mill requires a high-performance and reliable gauging system. This is of paramount importance due to the near 100% up-time requirements of modern cold rolling mills and to ensure precise and correct product thickness prior to final processing and shipment to the customer.

Mechanical contact encoders have difficulty measuring the length and speed of the strip with any degree of accuracy due to slippage and debris buildup on the rotating measurement wheel. These encoders also experience mechanical failure and require operators to perform routine calibration, maintenance and production line adjustments -- causing downtime.

Accurately Controlling Mass Flow

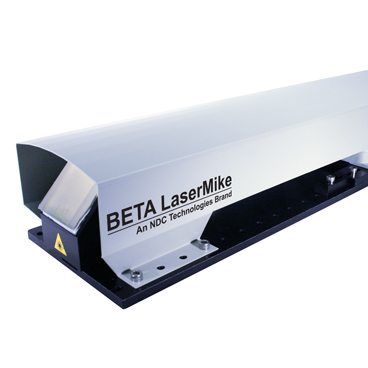

Modern rolling mills are using the LaserSpeed® Pro non-contact laser gauge to directly measure the strip speed in Mass Flow Automatic Gauge Control (MFAGC) and elongation applications that require differential speed control. This new generation of laser-based gauge provides high measurement accuracy and high performance, and eliminates the measurement errors associated with mechanical encoders. LaserSpeed Pro can measure strip speeds with better than +/-0.03% accuracy and +/-0.02% repeatability. It has no moving parts, eliminates all slippage errors and is permanently calibrated.

NDC's gauging solutions deliver measurement performance exceeding that required for the newest, most technologically advanced rolling mills built today.

Check out our LaserSpeed Pro gauging solution below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP