Galvanizing and Electrolytic Tinning Lines

Ensure Coating Quality and Thickness

For galvanizing and electrolytic tinning lines, coating uniformity and meeting minimum tolerances are important to ensure product quality and reduce cost. In addition, the accurate final length of the product is critical for further downstream processing.

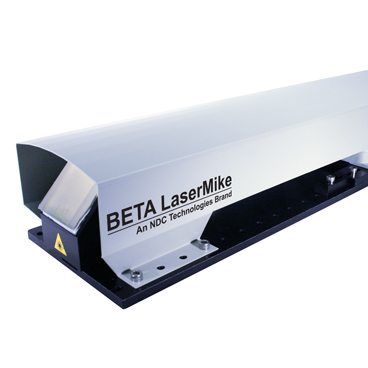

NDC's LaserSpeed® Pro non-contact gauge can precisely measure the final length of product during these processes. This gauge uses Laser Dopper Velocimetry to directly measure the surface speed of the product. The speed data is converted to pulses at a rate proportional to the speed. External counters or PLCs count the pulse to determine length. Measurements are made with better than +/-0.03% accuracy.

The LaserSpeed Pro gauge can be easily installed in the process for long-term continuous use. It is permanently calibrated and is a direct replacement for contact mechanical encoders. For high reliability, the LaserSpeed Pro gauge can installed in an environmental enclosure for protection against harsh environments.

Check out our LaserSpeed Pro gauging solution below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP