Metals Processing

Hot Rolling Mill

Lower Costs, Reduce Time to Market and Improve Quality

During the hot rolling mill process, many factors are taken into account to ensure the final rolled product meets the desired thickness tolerances and ultimate quality requirements. With the goal of reducing material consumption and manufacturing costs, it's imperative for manufacturers to achieve minimum and nominal thickness tolerances by rolling down the strip as close as possible to the minimum thickness, and achieving thickness uniformity.

Key to achieving these goals is employing a length and speed measurement solution to accurately control the differential speed of product entering and exiting the rolling stations, utilizing mass flow concept and elongation measurements.

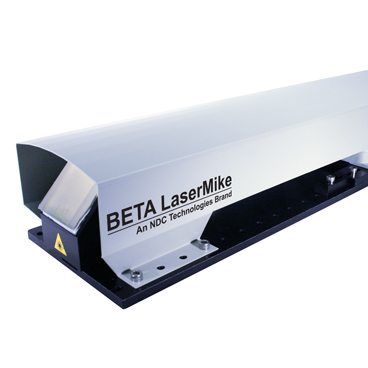

NDC has over 50 years of experience in measurement and control applications involving hot rolling mills. We've installed numerous LaserSpeed® Pro non-contact length and speed gauging systems across the globe at the leading manufacturing plants to improve product quality, increase productivity and drive manufacturing savings.

Check out our LaserSpeed Pro gauging solution below.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP