Metals Processing

Coating Weight and Coating Thickness

Improve Coating Quality and Reduced Production Costs with High-Accuracy, Repeatable Measurements

When applying any coating, uniformity and maintaining minimum tolerances are key to ensuring product quality and cost control. That’s why it is essential to precisely determine the coating weight online, rather than with fewer and delayed manual laboratory measurements or downstream at the next coil process. On-line measurements also allow for direct control of the coating application.

NDC's coating weight and coating thickness systems can precisely measure all coating types including oil, wax, lacquer, varnish, passivation (phosphate and titanate) and anti-fingerprint coatings – and help you control quality. Coatings can be both wet and dry depending on type and application. We offer Near Infrared gauging technologies to effectively gauge metal coatings though applications-specific configurations.

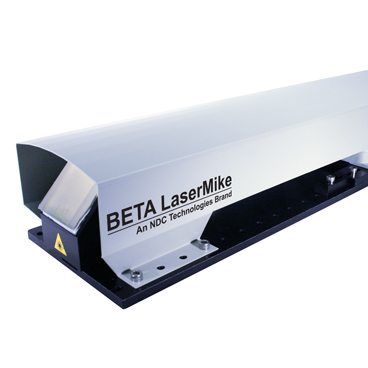

Length and Speed Measurements with Laser Precision

For controlling the length and speed of products during the coating process, NDC offers the LaserSpeed® Pro non-contact gauge. This laser-based gauge provides an accuracy of better than +/-0.03% with +/-0.02% repeatability.

Defects identified by the thickness gauges can be located in the strip by length by utilizing the LaserSpeed Pro gauge measurements.

Check out our coating and length and speed gauging solutions below for your unique process applications.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP