Metals Processing

Differential Speed and Elongation

Accurate, Stable Measurements Control the Dimensional Accuracy of Products

Accurately measuring the length and speed at the entry and exit sides of an aluminum cold-rolling station to control elongation and reduce product thickness to specified dimensions is critically important to producing a quality product. Speed fluctuations directly affect the elongation process, subsequent processing steps and important dimensional characteristics that ultimately affect product quality.

To measure elongation ratios and differential speeds, you typically need the entry speed and the exit speed of the mill station to calculate the elongation ratio. Mills that have used contact rollers and tachometers to obtain speed measurements have experienced huge errors in calculating the elongation ratio when the mill accelerates and decelerates. The main causes were due to slippage errors between the roller and the strip, and errors due to roller diameter wear.

How Non-Contact Laser Gauging Helps

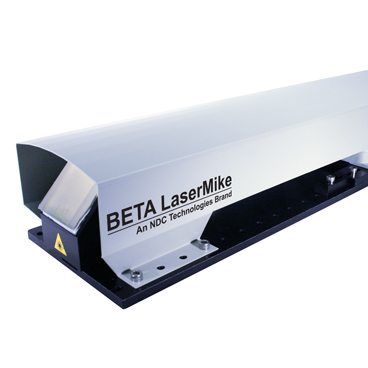

The LaserSpeed® Pro gauge eliminates those costly errors associated with contact mechanical measurement devices. It uses Dual Beam Laser Interferometry to obtain speed measurements without contacting the product. Two LaserSpeed Pro gauges are used to measure the entry speed and exit speed of the mill stations. By using the Mass Flow concept, the elongation of the product or strip and the product gauge or thickness is controlled to customer specifications. LaserSpeed Pro measures the speed of the product directly, thereby eliminating slippage and mechanical wear problems. And, it delivers an accuracy of better than ±0.03% and repeatability of ±0.02% to effectively control elongation processes.

LaserSpeed Pro can be used in the following process locations for elongation and differential speed control:

- Temper mills

- Skin pass mills

- Cold rolling mills

- Hot Rolling Mills

- Tension leveler lines

- Bar and rod draw reduction lines

- Wire draw lines

- And more

Check out our LaserSpeed Pro gauge below for your unique process application.

Can't find what you are looking for?

If you're looking for a particular product or system solution to an application, or a specific resource item, simply enter the keywords below to search and view details.

If you still can't find what you're looking for and would like to speak with one of our product and application specialists near you, you're just a click away.

LET US HELP